Difference between revisions of "Cruise control"

| Line 64: | Line 64: | ||

The model for the system above can be built using the [[https:python-control.org|Python Control Toolbox]]. The code blocks in this section can be used to generate the plots above. | The model for the system above can be built using the [[https:python-control.org|Python Control Toolbox]]. The code blocks in this section can be used to generate the plots above. | ||

| − | {{Code block|Package initialization (from [[ | + | {{Code block|Package initialization (from [[https:github.com/murrayrm/fbs2e-python/blob/main/cruise.py|cruise.py]])}} |

{{Code start}} | {{Code start}} | ||

import numpy as np | import numpy as np | ||

Revision as of 15:49, 28 May 2023

| GitHub URL | https://github.com/murrayrm/fbs2e-python/blob/main/cruise.py |

|---|---|

| Requires | python-control |

This page documents the cruise control system that is used as a running example throughout the text. A detailed description of the dynamics of this system are presented in Chapter 4 - Examples. This page contains a description of the system, including the models and commands used to generate some of the plots in the text.

Note: the Python code on this page makes use of the Python Control Systems Library, an open source software toolbox for control systems analysis.

Introduction

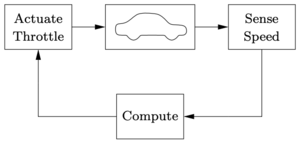

Cruise control is the term used to describe a control system that regulates the speed of an automobile. Cruise control was commercially introduced in 1958 as an option on the Chrysler Imperial. The basic operation of a cruise controller is to sense the speed of the vehicle, compare this speed to a desired reference, and then accelerate or decelerate the car as required. The figure to the right shows a block diagram of this feedback system.

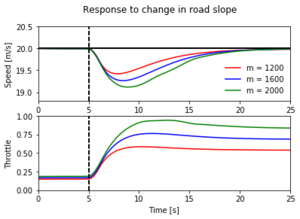

A simple control algorithm for controlling the speed is to use a "proportional plus integral" feedback. In this algorithm, we choose the amount of gas flowing to the engine based on both the error between the current and desired speed, and the integral of that error. The plot on the right shows the results of this feedback for a step change in the desired speed and a variety of different masses for the car (which might result from having a different number of passengers or towing a trailer). Notice that independent of the mass (which varies by 25% of the total weight of the car), the steady state speed of the vehicle always approaches the desired speed and achieves that speed within approximately 10-15 seconds. Thus the performance of the system is robust with respect to this uncertainty.

Dynamic model

To develop a mathematical model we start with a force balance for the car body. Let Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle v} be the speed of the car, Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle m} the total mass (including passengers), Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle F} the force generated by the contact of the wheels with the road, and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle F_\text{d}} the disturbance force due to gravity, friction and aerodynamic drag. The equation of motion of the car is simply

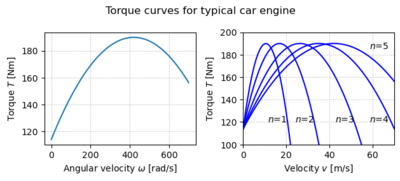

The force Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle F} is generated by the engine, whose torque is proportional to the rate of fuel injection, which is itself proportional to a control signal Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle 0 \leq u \leq 1} that controls the throttle position. The torque also depends on engine speed Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \omega} . A simple representation of the torque at full throttle is given by the torque curve

where the maximum torque Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle T_\text{m}} is obtained at engine speed Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \omega_\text{m}} . Typical parameters are Failed to parse (Conversion error. Server ("https://en.wikipedia.org/api/rest_") reported: "Cannot get mml. Server problem."): {\displaystyle T_{m}=190} Nm, Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \omega_m} = 420 rad/s (about 4000 RPM) and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \beta = 0.4} .

Let Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle n} be the gear ratio and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle r} the wheel radius. The engine speed is related to the velocity through the expression

and the driving force can be written as

Typical values of Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \alpha_n} for gears 1 through 5 are Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \alpha_1 = 40} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \alpha_2 = 25} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \alpha_3 = 16} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \alpha_4 = 12} and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \alpha_5 = 10} . The inverse of Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \alpha_n} has a physical interpretation as the effective wheel radius. The figure to the right shows the torque as a function of vehicle speed. The figure shows that the effect of the gear is to "flatten" the torque curve so that an almost full torque can be obtained almost over the whole speed range.

The disturbance force Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle F_\text{d}} has three major components: Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle F_\text{g}} , the forces due to gravity; Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle F_\text{r}} , the forces due to rolling friction; and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle F_\text{a}} , the aerodynamic drag. Letting the slope of the road be Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \theta} , gravity gives the force Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle F_\text{g} = m g \sin\theta} , where Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle g = 9.8\, \text{m}/\text{s}^2} is the gravitational constant. A simple model of rolling friction is

where Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle C_\text{r}} is the coefficient of rolling friction and sgn(Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle v} ) is the sign of Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle v} or zero if Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle v = 0} . A typical value for the coefficient of rolling friction is Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle C_\text{r} = 0.01} . Finally, the aerodynamic drag is proportional to the square of the speed:

where Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \rho} is the density of air, Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle C_d} is the shape-dependent aerodynamic drag coefficient and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle A} is the frontal area of the car. Typical parameters are Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \rho = } 1.3 k/mFailed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle {}^3} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle C_\text{d} = 0.32} and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle A =} 2.4 mFailed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle {}^2} .

Python code

The model for the system above can be built using the Python Control Toolbox. The code blocks in this section can be used to generate the plots above.

import numpy as np import matplotlib as mpl import matplotlib.pyplot as plt from math import pi import control as ct

def vehicle_update(t, x, u, params={}):

"""Vehicle dynamics for cruise control system.

Parameters

----------

x : array

System state: car velocity in m/s

u : array

System input: [throttle, gear, road_slope], where throttle is

a float between 0 and 1, gear is an integer between 1 and 5,

and road_slope is in rad.

Returns

-------

float

Vehicle acceleration

"""

from math import copysign, sin

sign = lambda x: copysign(1, x) # define the sign() function

# Set up the system parameters

m = params.get('m', 1600.) # vehicle mass, kg

g = params.get('g', 9.8) # gravitational constant, m/s^2

Cr = params.get('Cr', 0.01) # coefficient of rolling friction

Cd = params.get('Cd', 0.32) # drag coefficient

rho = params.get('rho', 1.3) # density of air, kg/m^3

A = params.get('A', 2.4) # car area, m^2

alpha = params.get(

'alpha', [40, 25, 16, 12, 10]) # gear ratio / wheel radius

# Define variables for vehicle state and inputs

v = x[0] # vehicle velocity

throttle = np.clip(u[0], 0, 1) # vehicle throttle

gear = u[1] # vehicle gear

theta = u[2] # road slope

# Force generated by the engine

omega = alpha[int(gear)-1] * v # engine angular speed

F = alpha[int(gear)-1] * motor_torque(omega, params) * throttle

# Disturbance forces

#

# The disturbance force Fd has three major components: Fg, the forces due

# to gravity; Fr, the forces due to rolling friction; and Fa, the

# aerodynamic drag.

# Letting the slope of the road be \theta (theta), gravity gives the

# force Fg = m g sin \theta.

Fg = m * g * sin(theta)

# A simple model of rolling friction is Fr = m g Cr sgn(v), where Cr is

# the coefficient of rolling friction and sgn(v) is the sign of v (±1) or

# zero if v = 0.

Fr = m * g * Cr * sign(v)

# The aerodynamic drag is proportional to the square of the speed: Fa =

# 1/2 \rho Cd A |v| v, where \rho is the density of air, Cd is the

# shape-dependent aerodynamic drag coefficient, and A is the frontal area

# of the car.

Fa = 1/2 * rho * Cd * A * abs(v) * v

# Final acceleration on the car

Fd = Fg + Fr + Fa

dv = (F - Fd) / m

return dv

def motor_torque(omega, params={}):

# Set up the system parameters

Tm = params.get('Tm', 190.) # engine torque constant

omega_m = params.get('omega_m', 420.) # peak engine angular speed

beta = params.get('beta', 0.4) # peak engine rolloff

return np.clip(Tm * (1 - beta * (omega/omega_m - 1)**2), 0, None)

vehicle = ct.NonlinearIOSystem(

vehicle_update, None, name='vehicle',

inputs = ('u', 'gear', 'theta'), outputs = ('v'), states=('v'))

# Figure 4.2a - single torque curve as function of omega

omega_range = np.linspace(0, 700, 701)

plt.subplot(2, 2, 1)

plt.plot(omega_range, [motor_torque(w) for w in omega_range])

plt.xlabel('Angular velocity $\omega$ [rad/s]')

plt.ylabel('Torque $T$ [Nm]')

plt.grid(True, linestyle='dotted')

# Figure 4.2b - torque curves in different gears, as function of velocity

plt.subplot(2, 2, 2)

v_range = np.linspace(0, 70, 71)

alpha = [40, 25, 16, 12, 10]

for gear in range(5):

omega_range = alpha[gear] * v_range

plt.plot(v_range, [motor_torque(w) for w in omega_range],

color='blue', linestyle='solid')

# Set up the axes and style

plt.axis([0, 70, 100, 200])

plt.grid(True, linestyle='dotted')

# Add labels

plt.text(11.5, 120, '$n$=1')

plt.text(24, 120, '$n$=2')

plt.text(42.5, 120, '$n$=3')

plt.text(58.5, 120, '$n$=4')

plt.text(58.5, 185, '$n$=5')

plt.xlabel('Velocity $v$ [m/s]')

plt.ylabel('Torque $T$ [Nm]')

plt.suptitle('Torque curves for typical car engine');

plt.tight_layout()

plt.savefig("cruise-gearcurves.png", bbox_inches='tight')

# Construct a PI controller with rolloff, as a transfer function

Kp = 0.5 # proportional gain

Ki = 0.1 # integral gain

control_pi = ct.tf2io(

ct.TransferFunction([Kp, Ki], [1, 0.01*Ki/Kp]),

name='control', inputs='u', outputs='y')

cruise_pi = ct.InterconnectedSystem(

(vehicle, control_pi), name='cruise',

connections = [('control.u', '-vehicle.v'), ('vehicle.u', 'control.y')],

inplist = ('control.u', 'vehicle.gear', 'vehicle.theta'), inputs = ('vref', 'gear', 'theta'),

outlist = ('vehicle.v', 'vehicle.u'), outputs = ('v', 'u'))

# Define a generator for creating a "standard" cruise control plot

def cruise_plot(sys, t, y, t_hill=5, vref=20, antiwindup=False, linetype='b-',

subplots=[None, None]):

# Figure out the plot bounds and indices

v_min = vref-1.2; v_max = vref+0.5; v_ind = sys.find_output('v')

u_min = 0; u_max = 2 if antiwindup else 1; u_ind = sys.find_output('u')

# Make sure the upper and lower bounds on v are OK

while max(y[v_ind]) > v_max: v_max += 1

while min(y[v_ind]) < v_min: v_min -= 1

# Create arrays for return values

subplot_axes = subplots.copy()

# Velocity profile

if subplot_axes[0] is None:

subplot_axes[0] = plt.subplot(2, 1, 1)

else:

plt.sca(subplots[0])

plt.plot(t, y[v_ind], linetype)

plt.plot(t, vref*np.ones(t.shape), 'k-')

plt.plot([t_hill, t_hill], [v_min, v_max], 'k--')

plt.axis([0, t[-1], v_min, v_max])

plt.xlabel('Time $t$ [s]')

plt.ylabel('Velocity $v$ [m/s]')

# Commanded input profile

if subplot_axes[1] is None:

subplot_axes[1] = plt.subplot(2, 1, 2)

else:

plt.sca(subplots[1])

plt.plot(t, y[u_ind], 'r--' if antiwindup else linetype)

plt.plot([t_hill, t_hill], [u_min, u_max], 'k--')

plt.axis([0, t[-1], u_min, u_max])

plt.xlabel('Time $t$ [s]')

plt.ylabel('Throttle $u$')

# Applied input profile

if antiwindup:

plt.plot(t, np.clip(y[u_ind], 0, 1), linetype)

plt.legend(['Commanded', 'Applied'], frameon=False)

return subplot_axes

# Define the time and input vectors

T = np.linspace(0, 25, 101)

vref = 20 * np.ones(T.shape)

gear = 4 * np.ones(T.shape)

theta0 = np.zeros(T.shape)

# Effect of a hill at t = 5 seconds

theta_hill = np.array([

0 if t <= 5 else

4./180. * pi * (t-5) if t <= 6 else

4./180. * pi for t in T])

# Simulate and plot

plt.figure()

plt.suptitle('Response to change in road slope')

subplots = [None, None]

linecolor = ['red', 'blue', 'green']

handles = []

for i, m in enumerate([1200, 1600, 2000]):

# Compute the equilibrium state for the system

X0, U0 = ct.find_eqpt(

cruise_pi, [vref[0], 0], [vref[0], gear[0], theta0[0]],

iu=[1, 2], y0=[vref[0], 0], iy=[0], params={'m':m})

t, y = ct.input_output_response(

cruise_pi, T, [vref, gear, theta_hill], X0, params={'m':m})

subplots = cruise_plot(cruise_pi, t, y, t_hill=5, subplots=subplots,

linetype=linecolor[i][0] + '-')

handles.append(mpl.lines.Line2D([], [], color=linecolor[i],

linestyle='-', label="m = %d" % m))

# Add labels to the plots

plt.sca(subplots[0])

plt.ylabel('Speed [m/s]')

plt.legend(handles=handles, frameon=False, loc='lower right');

plt.sca(subplots[1])

plt.ylabel('Throttle')

plt.xlabel('Time [s]');

plt.savefig("cruise-speedresp.png", bbox_inches='tight')

Linearized Dynamics

To explore the behavior of the cruise control system near the equilibrium point we will linearize the system. A Taylor series expansion of the dynamics around the equilibrium point gives

where

Notice that the term corresponding to rolling friction disappears if Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle v > 0} . For a car in fourth gear with Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle v_\text{e} = 20} m/s, Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \theta_\text{e} = 0} , and the numerical values from above, the equilibrium value for the throttle is Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle u_\text{e}=0.1687} and the parameters are Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle a = 0.01} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle b = 1.32} , and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle b_\text{g} = 9.8} . This linear model describes how small perturbations in the velocity about the nominal speed evolve in time.

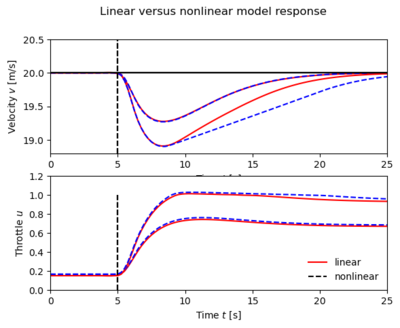

We apply the PI controller above to the case where the car is running with constant speed on a horizontal road and the system has stabilized so that the vehicle speed and the controller output are constant. The figure to the right shows what happens when the car encounters a hill with a slope of 4 degrees and a hill with a slope of 6 degrees at time Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle t =\,}

5 seconds. The results for the nonlinear model are dashed curves and those for the linear model are solid curves. The differences between the curves are very small (especially for Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \theta =\,}

4 degrees), and control design based on the linearized model is thus validated.

Python code

# Find the equilibrium point for the system

Xeq, Ueq = ct.find_eqpt(

vehicle, [vref[0]], [0, gear[0], theta0[0]], y0=[vref[0]], iu=[1, 2])

print("Xeq = ", Xeq, "\nUeq = ", Ueq)

# Compute the linearized system at the eq pt

vehlin = ct.linearize(vehicle, Xeq, [Ueq[0], gear[0], 0], name='vehlin', copy=True)

def pi_update(t, x, u, params={}):

# Get the controller parameters that we need

ki = params.get('ki', 0.1)

kaw = params.get('kaw', 2) # anti-windup gain

# Assign variables for inputs and states (for readability)

v = u[0] # current velocity

vref = u[1] # reference velocity

z = x[0] # integrated error

# Compute the nominal controller output (needed for anti-windup)

u_a = pi_output(t, x, u, params)

# Compute anti-windup compensation (scale by ki to account for structure)

u_aw = kaw/ki * (np.clip(u_a, 0, 1) - u_a) if ki != 0 else 0

# State is the integrated error, minus anti-windup compensation

return (vref - v) + u_aw

def pi_output(t, x, u, params={}):

# Get the controller parameters that we need

kp = params.get('kp', 0.5)

ki = params.get('ki', 0.1)

# Assign variables for inputs and states (for readability)

v = u[0] # current velocity

vref = u[1] # reference velocity

z = x[0] # integrated error

# PI controller

return kp * (vref - v) + ki * z

control_pi_aw = ct.NonlinearIOSystem(

pi_update, pi_output, name='control',

inputs = ['v', 'vref'], outputs = ['u'], states = ['z'],

params = {'kp':0.5, 'ki':0.1})

# Create a closed loop controller for the linear system

cruise_lin = ct.InterconnectedSystem(

(vehlin, control_pi_aw), name='cruise_lin',

connections=(

('vehlin.u', 'control.u'),

('control.v', 'vehlin.v')),

inplist=('control.vref', 'vehlin.gear', 'vehlin.theta'),

outlist=('control.u', 'vehlin.v'), outputs=['u', 'v'])

# Create a closed loop controller for the nonlinear system

cruise_nonlin = ct.InterconnectedSystem(

(vehicle, control_pi_aw), name='cruise_nonlin',

connections=(

('vehicle.u', 'control.u'),

('control.v', 'vehicle.v')),

inplist=('control.vref', 'vehicle.gear', 'vehicle.theta'),

outlist=('control.u', 'vehicle.v'), outputs=['u', 'v'])

# Linear response

X0_lin, U0 = ct.find_eqpt(

cruise_lin, [vref[0], 0], [vref[0], gear[0], theta0[0]],

y0=[0, vref[0]], iu=[1, 2], iy=[1])

t, y = ct.input_output_response(cruise_lin, T, [vref, gear, theta_hill], X0_lin)

subplots = cruise_plot(cruise_lin, t, y, t_hill=5, linetype='r-')

# Nonlinear response

X0_nonlin, U0 = ct.find_eqpt(

cruise_nonlin, [vref[0], 0], [vref[0], gear[0], theta0[0]],

y0=[0, vref[0]], iu=[1, 2], iy=[1])

t, y = ct.input_output_response(cruise_nonlin, T, [vref, gear, theta_hill], X0_nonlin)

subplots = cruise_plot(cruise_nonlin, t, y, t_hill=5, subplots=subplots, linetype='b--')

# Add a legend to identify linear vs nonlinear

plt.legend(['linear', 'nonlinear'], frameon=False, loc='lower right')

# Add two more simulations for 6 degree hill instead of 4 degree

t, y = ct.input_output_response(cruise_lin, T, [vref, gear, theta_hill*1.5], X0_lin)

subplots = cruise_plot(cruise_lin, t, y, t_hill=5, subplots=subplots, linetype='r-')

t, y = ct.input_output_response(cruise_nonlin, T, [vref, gear, theta_hill*1.5], X0_nonlin)

subplots = cruise_plot(cruise_nonlin, t, y, t_hill=5, subplots=subplots, linetype='b--')

# Add titles and legends and save the figure

plt.suptitle('Linear versus nonlinear model response')

plt.sca(subplots[1]); plt.axis([0, 25, 0, 1.2])

plt.savefig("cruise-linear_vs_nonlinear.png", bbox_inches='tight')

State Space Control

The linearized dynamics of the process around an equilibrium point Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle v_\text{e}} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle u_\text{e}} are given by

where Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle x = v - v_\text{e}} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle = u - u_\text{e}} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle m} is the mass of the car, and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \theta} is the angle of the road. The constants Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle a} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle b} , and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle b_\text{g}} depend on the properties of the car and are given above.

If we augment the system with an integrator, the system dynamics become

or, in state space form,

Note that when the system is at equilibrium, we have that Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \dot z = 0} , which implies that the vehicle speed Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle v = v_\text{e} + x} should be equal to the desired reference speed Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle v_\text{r}} . Our controller will be of the form

and the gains Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{p}} , Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{i}} , and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{f}} will be chosen to stabilize the system and provide the correct input for the reference speed.

Assume that we wish to design the closed loop system to have the characteristic polynomial

Setting the disturbance Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \theta = 0} , the characteristic polynomial of the closed loop system is given by

and hence we set

The resulting controller stabilizes the system and hence brings Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \dot z = y - v_\text{r}} to zero, resulting in perfect tracking. Notice that even if we have a small error in the values of the parameters defining the system, as long as the closed loop eigenvalues are still stable, then the tracking error will approach zero. Thus the exact calibration required in our previous approach (using Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{f}} ) is not needed here. Indeed, we can even choose Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{f} = 0} and let the feedback controller do all of the work. However, Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{f}} does influence the transient response to reference signals and setting it properly will generally give a more favorable response.

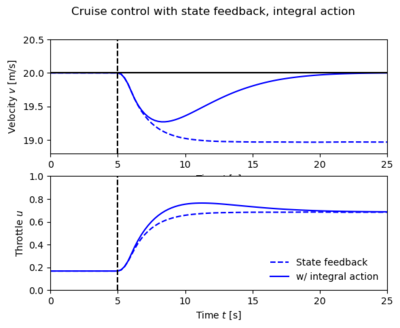

Integral feedback can also be used to compensate for constant disturbances. The figure to the right shows the results of a simulation in which the car encounters a hill with angle Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \theta = 4} degrees at Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle t = } 5 seconds. The steady-state values of the throttle for a state feedback controller and a controller with integral action are very close, but the corresponding values of the car velocity are quite different. The reason for this is that the zero frequency gain from throttle to velocity is Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle -b/a=130} is high. The stability of the system is not affected by this external disturbance, and so we once again see that the car's velocity converges to the reference speed. This ability to handle constant disturbances is a general property of controllers with integral feedback.

Python code

def sf_update(t, z, u, params={}):

y, r = u[1], u[2]

return y - r

def sf_output(t, z, u, params={}):

# Get the controller parameters that we need

K = params.get('K', 0)

ki = params.get('ki', 0)

kf = params.get('kf', 0)

xd = params.get('xd', 0)

yd = params.get('yd', 0)

ud = params.get('ud', 0)

# Get the system state and reference input

x, y, r = u[0], u[1], u[2]

return ud - K * (x - xd) - ki * z + kf * (r - yd)

# Create the input/output system for the controller

control_sf = ct.NonlinearIOSystem(

sf_update, sf_output, name='control',

inputs=('x', 'y', 'r'),

outputs=('u'),

states=('z'))

# Create the closed loop system for the state space controller

cruise_sf = ct.InterconnectedSystem(

(vehicle, control_sf), name='cruise',

connections=(

('vehicle.u', 'control.u'),

('control.x', 'vehicle.v'),

('control.y', 'vehicle.v')),

inplist=('control.r', 'vehicle.gear', 'vehicle.theta'),

outlist=('control.u', 'vehicle.v'), outputs=['u', 'v'])

# Construct the gain matrices for the system

A, B, C = vehlin.A, vehlin.B[0, 0], vehlin.C

K = 0.5

kf = -1 / (C * np.linalg.inv(A - B * K) * B)

# Compute the steady state velocity and throttle setting

xd = Xeq[0]

ud = Ueq[0]

yd = vref[-1]

# Response of the system with no integral feedback term

t, y_sfb = ct.input_output_response(

cruise_sf, T, [vref, gear, theta_hill], [Xeq[0], 0],

params={'K':K, 'ki':0.0, 'kf':kf, 'xd':xd, 'ud':ud, 'yd':yd})

subplots = cruise_plot(cruise_sf, t, y_sfb, t_hill=5, linetype='b--')

# Response of the system with state feedback + integral action

t, y_sfb_int = ct.input_output_response(

cruise_sf, T, [vref, gear, theta_hill], [Xeq[0], 0],

params={'K':K, 'ki':0.1, 'kf':kf, 'xd':xd, 'ud':ud, 'yd':yd})

cruise_plot(cruise_sf, t, y_sfb_int, t_hill=5, linetype='b-', subplots=subplots)

# Add title and legend

plt.suptitle('Cruise control with state feedback, integral action')

p_line = mpl.lines.Line2D([], [], color='blue', linestyle='--', label='State feedback')

pi_line = mpl.lines.Line2D([], [], color='blue', linestyle='-', label='w/ integral action')

plt.legend(handles=[p_line, pi_line], frameon=False, loc='lower right')

plt.savefig("cruise-statefbk.png", bbox_inches='tight')

PID Control

The dynamics of the system are given by a first-order system with the transfer function

With a PI controller the closed loop system has the characteristic polynomial

The closed loop poles can thus be assigned arbitrary values by proper choice of the controller gains Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{p}} and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{i}} . Requiring that the closed loop system have the characteristic polynomial

we find that the controller parameters are

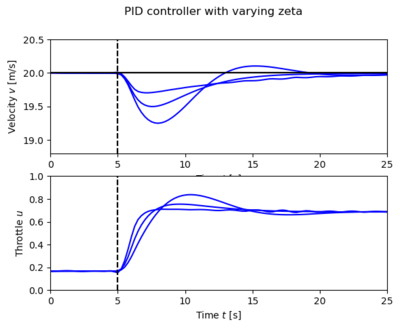

If we require a response of the closed loop system that is slower than that of the open loop system, a reasonable choice is Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle a_1 = a + \alpha} and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle a_2 = \alpha a} , where Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \alpha < a} determines the closed loop response. If a response faster than that of the open loop system is required, a possible choice is Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle a_1 = 2 \zeta_\text{c} \omega_\text{c}} and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle a_2 = \omega_\text{c}^2} , where Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \omega_\text{c}} and Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \zeta_\text{c}} are the undamped natural frequency and damping ratio of the dominant mode.

To design a PI controller we choose Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \zeta_\text{c} = 1} to obtain a response without overshoot. The choice of Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \omega_\text{c}} is a compromise between response speed and control actions: a large value gives a fast response, but it requires fast control action. The largest velocity error decreases with increasing Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \omega_\text{c}} , but the control signal also changes more rapidly. In the simple model it was assumed that the force responds instantaneously to throttle commands. For rapid changes there may be additional dynamics that have to be accounted for. There are also physical limits to the rate of change of the force, which also restricts the admissible value of Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \omega_\text{c}} . A reasonable choice of Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle \omega_\text{c}} is in the range 0.5--1.0.

Python code

# Get the transfer function from throttle input + hill to vehicle speed P = ct.ss2tf(vehlin[0, 0]) # Construction a controller that cancels the pole a = -P.pole()[0] b = np.real(P(0)) * a

# Fix \omega_0 and vary \zeta

w0 = 0.5

subplots = [None, None]

for zeta in [0.5, 1, 2]:

# Create the controller transfer function (as an I/O system)

kp = (2*zeta*w0 - a)/b

ki = w0**2 / b

control_tf = ct.tf2io(

ct.TransferFunction([kp, ki], [1, 0.01*ki/kp]),

name='control', inputs='u', outputs='y')

# Construct the closed loop system by interconnecting process and controller

cruise_tf = ct.InterconnectedSystem(

(vehicle, control_tf), name='cruise',

connections = [('control.u', '-vehicle.v'), ('vehicle.u', 'control.y')],

inplist = ('control.u', 'vehicle.gear', 'vehicle.theta'),

inputs = ('vref', 'gear', 'theta'),

outlist = ('vehicle.v', 'vehicle.u'), outputs = ('v', 'u'))

# Plot the velocity response

X0, U0 = ct.find_eqpt(

cruise_tf, [vref[0], 0], [vref[0], gear[0], theta_hill[0]],

iu=[1, 2], y0=[vref[0], 0], iy=[0])

t, y = ct.input_output_response(cruise_tf, T, [vref, gear, theta_hill], X0)

subplots = cruise_plot(cruise_tf, t, y, t_hill=5, subplots=subplots)

plt.suptitle('PID controller with varying zeta')

plt.savefig("cruise-pid-sweep-zeta.png", bbox_inches='tight')

zeta = 1

subplots = [None, None]

for w0 in [0.2, 0.5, 1]:

# Create the controller transfer function (as an I/O system)

kp = (2*zeta*w0 - a)/b

ki = w0**2 / b

control_tf = ct.tf2io(

ct.TransferFunction([kp, ki], [1, 0.01*ki/kp]),

name='control', inputs='u', outputs='y')

# Construct the closed loop system by interconnecting process and controller

cruise_tf = ct.InterconnectedSystem(

(vehicle, control_tf), name='cruise',

connections = [('control.u', '-vehicle.v'), ('vehicle.u', 'control.y')],

inplist = ('control.u', 'vehicle.gear', 'vehicle.theta'),

inputs = ('vref', 'gear', 'theta'),

outlist = ('vehicle.v', 'vehicle.u'), outputs = ('v', 'u'))

# Plot the velocity response

X0, U0 = ct.find_eqpt(

cruise_tf, [vref[0], 0], [vref[0], gear[0], theta_hill[0]],

iu=[1, 2], y0=[vref[0], 0], iy=[0])

t, y = ct.input_output_response(cruise_tf, T, [vref, gear, theta_hill], X0)

subplots = cruise_plot(cruise_tf, t, y, t_hill=5, subplots=subplots)

plt.suptitle('PID controller with varying omega')

plt.savefig("cruise-pid-sweep-omega.png", bbox_inches='tight')

Anti-windup compensation

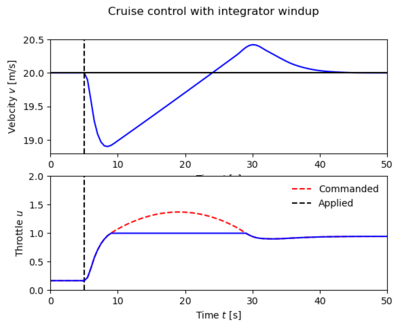

The windup effect is illustrated in the left figure below, which shows what happens when a car encounters a hill that is so steep (6 degrees) that the throttle saturates when the cruise controller attempts to maintain speed. When encountering the slope at time Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle t=5} , the velocity decreases and the throttle increases to generate more torque. However, the torque required is so large that the throttle saturates. The error decreases slowly because the torque generated by the engine is just a little larger than the torque required to compensate for gravity. The error is large and the integral continues to build up until the error reaches zero at time 25, but the controller output is still larger than the saturation limit and the actuator remains saturated. The integral term starts to decrease and the velocity settles to the desired value at time Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle t = 40} . Also notice the large overshoot.

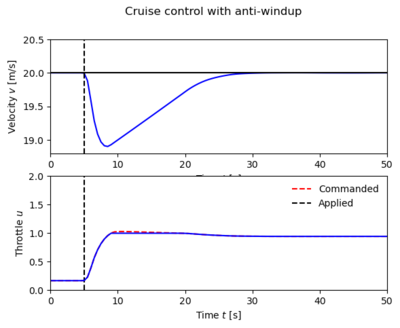

The right figure below shows what happens when a controller with anti-windup is applied to the system. Because of the feedback from the actuator model, the output of the integrator is quickly reset to a value such that the controller output is at the saturation limit. The behavior is drastically different from that on the left and the large overshoot is avoided. The tracking gain used in the simulation is Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{aw} = 2} which is an order of magnitude larger than the integral gain Failed to parse (MathML with SVG or PNG fallback (recommended for modern browsers and accessibility tools): Invalid response ("Math extension cannot connect to Restbase.") from server "https://en.wikipedia.org/api/rest_v1/":): {\displaystyle k_\text{i} = 0.2} .

Python code

T = np.linspace(0, 50, 101)

vref = 20 * np.ones(T.shape)

theta_hill = [

0 if t <= 5 else

6./180. * pi * (t-5) if t <= 6 else

6./180. * pi for t in T]

# Compute the equilibrium throttle setting for the desired speed

X0, U0 = ct.find_eqpt(

cruise_nonlin, [vref[0], 0], [vref[0], gear[0], theta0[0]],

y0=[0, vref[0]], iu=[1, 2], iy=[1])

t, y = ct.input_output_response(

cruise_nonlin, T, [vref, gear, theta_hill], X0,

params={'kaw':0})

cruise_plot(cruise_nonlin, t, y, antiwindup=True);

plt.suptitle('Cruise control with integrator windup')

plt.savefig("cruise-windup.png", bbox_inches='tight')

t, y = ct.input_output_response(

cruise_nonlin, T, [vref, gear, theta_hill], X0,

params={'kaw':2})

cruise_plot(cruise_nonlin, t, y, antiwindup=True);

plt.suptitle('Cruise control with anti-windup')

plt.savefig("cruise-antiwindup.png", bbox_inches='tight')

Further Reading

- How Stuff Works: cruise control

- Wikipedia: cruise control